Rebuilding a 4T65E-HD - Part 3 reference material

#1

Thread Starter

Senior Member

Posts like a Corvette

Joined: Jan 2007

Posts: 1,451

Likes: 0

From: San Diego, CA

Forgot to mention, Master Kit was $175 shipped. Time to start putting some of this back together.

Second Clutch Assemble:

Parts laid out:

New clutch frictions soak in ATF for 30 minutes:

Moisten new 2nd piston lip with ATF:

Piston was a bear to push into place...much tighter than the old one. Here the spring and clip are in place and ready for the tool:

Invert the old piston and use as a "washer" to avoid ruining this spring:

Still leaves enough gap to push the snap ring into the groove:

Done:

Soaked clutches installed:

New 2nd clutch pack all done:

Driven Sprocket Support Components Assemble:

After looking at it more closely, the scoring inside the 4th piston (see earlier post) was not in the location of the inner lip seal, but rather only where it travels at the top edge of the driven support. So I decided to reuse the 4th clutch piston. New outer lip seal, moistened with ATF:

Installing an ATF-soaked new inner seal using a specially homemade tool (aka, very small flatblade that I ground all sharp edges off of):

It is crucial to get these lip seals seated properly, so that they sit in the groove with the lip sticking out all the way around. It'* also crucial not to nick or cut the seals; in some cases, I temporarily wrapped shafts in electrical tape while sliding on the seals to avoid running seals over grooves or sharp edges...this was in lieu of buying up all kinds of specialty Kent Moore J-tool seal protectors and slides. Also, you have to make sure that inner lips seat inside pistons properly and do not "roll up" as you reinstall the pistons...another use for the rounded-off flatblade.

4th piston, spring and snap ring done:

This is an older-style driven sprocket support that uses rubber "quad rings" under the split-ring teflon oil seals; newer style (not sure on the year cutoff) uses a different size teflon seal and does not use these quad rings. The Transtec kit comes with both types of teflon seal, and includes new Viton quad rings:

Input Clutch and Third Clutch Assemble:

There are two inner lip seals and an o-ring in this one, and they are tricky to get to:

I hope this shows what I meant earlier by the new Transtec lip seals being "long-lipped" compared to the OEM'*:

More tricky business installing these seals; definitely the most hair-raising part of this assembly:

The threaded rod on my cheapo clutch spring compressor tool is not long enough to go all the way through the input hub assembly, so I had to improvise:

Inner seals, pistons, springs, and snap rings reinstalled:

Pre-soaked 3rd clutches all in place:

Pre-soaked input clutches all in place:

----------------

All the reassembly in this post took me four hours, which is about 36 hours less than I thought it would take me. I will credit that to my awesome cardboard box and ziploc bag organizational system.

Now I have to take these assemblies to the lab and function-test the reinstalled piston and lip seals with compressed air to make sure all are properly installed. If they pass, then the most screw-uppable part of reassembly (IMO) is done, and I can order up all the Sonnax fixes and solenoids for the valve body.

I also have to come up with some clever way to install and size the three replacement teflon sealing rings on the input shaft hub:

There are j-tools for this, but I'll come up with something.

Second Clutch Assemble:

Parts laid out:

New clutch frictions soak in ATF for 30 minutes:

Moisten new 2nd piston lip with ATF:

Piston was a bear to push into place...much tighter than the old one. Here the spring and clip are in place and ready for the tool:

Invert the old piston and use as a "washer" to avoid ruining this spring:

Still leaves enough gap to push the snap ring into the groove:

Done:

Soaked clutches installed:

New 2nd clutch pack all done:

Driven Sprocket Support Components Assemble:

After looking at it more closely, the scoring inside the 4th piston (see earlier post) was not in the location of the inner lip seal, but rather only where it travels at the top edge of the driven support. So I decided to reuse the 4th clutch piston. New outer lip seal, moistened with ATF:

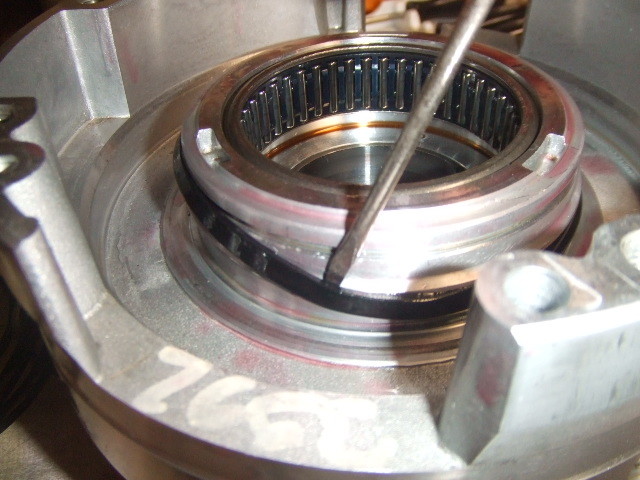

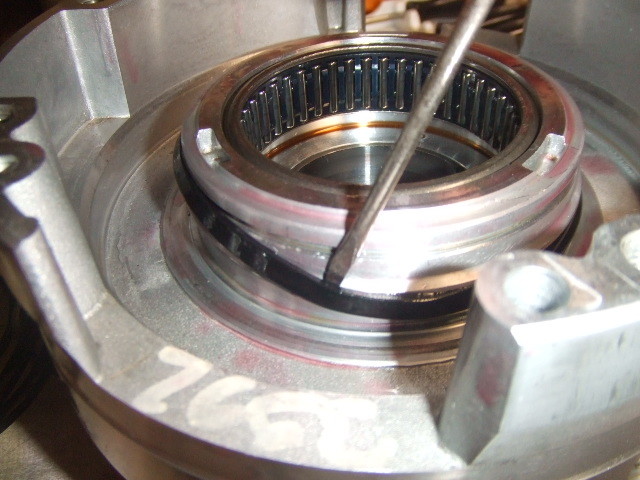

Installing an ATF-soaked new inner seal using a specially homemade tool (aka, very small flatblade that I ground all sharp edges off of):

It is crucial to get these lip seals seated properly, so that they sit in the groove with the lip sticking out all the way around. It'* also crucial not to nick or cut the seals; in some cases, I temporarily wrapped shafts in electrical tape while sliding on the seals to avoid running seals over grooves or sharp edges...this was in lieu of buying up all kinds of specialty Kent Moore J-tool seal protectors and slides. Also, you have to make sure that inner lips seat inside pistons properly and do not "roll up" as you reinstall the pistons...another use for the rounded-off flatblade.

4th piston, spring and snap ring done:

This is an older-style driven sprocket support that uses rubber "quad rings" under the split-ring teflon oil seals; newer style (not sure on the year cutoff) uses a different size teflon seal and does not use these quad rings. The Transtec kit comes with both types of teflon seal, and includes new Viton quad rings:

Input Clutch and Third Clutch Assemble:

There are two inner lip seals and an o-ring in this one, and they are tricky to get to:

I hope this shows what I meant earlier by the new Transtec lip seals being "long-lipped" compared to the OEM'*:

More tricky business installing these seals; definitely the most hair-raising part of this assembly:

The threaded rod on my cheapo clutch spring compressor tool is not long enough to go all the way through the input hub assembly, so I had to improvise:

Inner seals, pistons, springs, and snap rings reinstalled:

Pre-soaked 3rd clutches all in place:

Pre-soaked input clutches all in place:

----------------

All the reassembly in this post took me four hours, which is about 36 hours less than I thought it would take me. I will credit that to my awesome cardboard box and ziploc bag organizational system.

Now I have to take these assemblies to the lab and function-test the reinstalled piston and lip seals with compressed air to make sure all are properly installed. If they pass, then the most screw-uppable part of reassembly (IMO) is done, and I can order up all the Sonnax fixes and solenoids for the valve body.

I also have to come up with some clever way to install and size the three replacement teflon sealing rings on the input shaft hub:

There are j-tools for this, but I'll come up with something.

Thread

Thread Starter

Forum

Replies

Last Post