belt removal question

#1

Thread Starter

Senior Member

True Car Nut

Joined: Jun 2003

Posts: 2,493

Likes: 0

From: Climax Springs, Missouri

allright so i want to change out my serpentine belt, the proceedure in the chiltons is somewhat vague...the main steps i have in question are as follows

3. For 1996-1999 supercharged engines perform the following:

a. raise and safely support the vehicle

b. remove the right hand splash shield

c. remove the connector from the crank sensor

4. for 1996-1999 vehicles remove the engine mounting bracket lower nut, stud and spacer, carefully lower the vehicle

ok...so does that mean i dont have to raise my car? whats the purpose of raising the car anyway? does that also mean i dont have to remove the crank sensor connection? im just a little confused, ive been happy with the chiltons thus far, but this is a little vague, there arent really even pictures, youd think theyd have more stuff about such a common thing.

3. For 1996-1999 supercharged engines perform the following:

a. raise and safely support the vehicle

b. remove the right hand splash shield

c. remove the connector from the crank sensor

4. for 1996-1999 vehicles remove the engine mounting bracket lower nut, stud and spacer, carefully lower the vehicle

ok...so does that mean i dont have to raise my car? whats the purpose of raising the car anyway? does that also mean i dont have to remove the crank sensor connection? im just a little confused, ive been happy with the chiltons thus far, but this is a little vague, there arent really even pictures, youd think theyd have more stuff about such a common thing.

#2

You need to remove the lower engine mount stud and sleeve in order to replace the belt.

If you remove the passenger side splash guard, you'll then see the nut and stud to the right of the harmonic balancer and to the left of the AC compressor. You need to remove the nut, then the sleeve but you'll notice the crank sensor plug is in your way. I can do it without removing the plug but I've done it many times.

There is more to the proceedure;

The engine should be supported while the engine is partly disconnected. You can use a jack under the oil pan with a piece of wood to spread the load. Do not jack the engine, just support it.

The stud enters the coolant passages in the block. The FSM says to drain the coolant first. I don't bother with that and haven't noticed any coolant loss. I use teflon tape on the threads to reinstall rather than thread sealant, it'* a little easier.

It'* not difficult, you'll understand as soon as you're able to look at it.

Hope this helps.

Cheers,

If you remove the passenger side splash guard, you'll then see the nut and stud to the right of the harmonic balancer and to the left of the AC compressor. You need to remove the nut, then the sleeve but you'll notice the crank sensor plug is in your way. I can do it without removing the plug but I've done it many times.

There is more to the proceedure;

The engine should be supported while the engine is partly disconnected. You can use a jack under the oil pan with a piece of wood to spread the load. Do not jack the engine, just support it.

The stud enters the coolant passages in the block. The FSM says to drain the coolant first. I don't bother with that and haven't noticed any coolant loss. I use teflon tape on the threads to reinstall rather than thread sealant, it'* a little easier.

It'* not difficult, you'll understand as soon as you're able to look at it.

Hope this helps.

Cheers,

#3

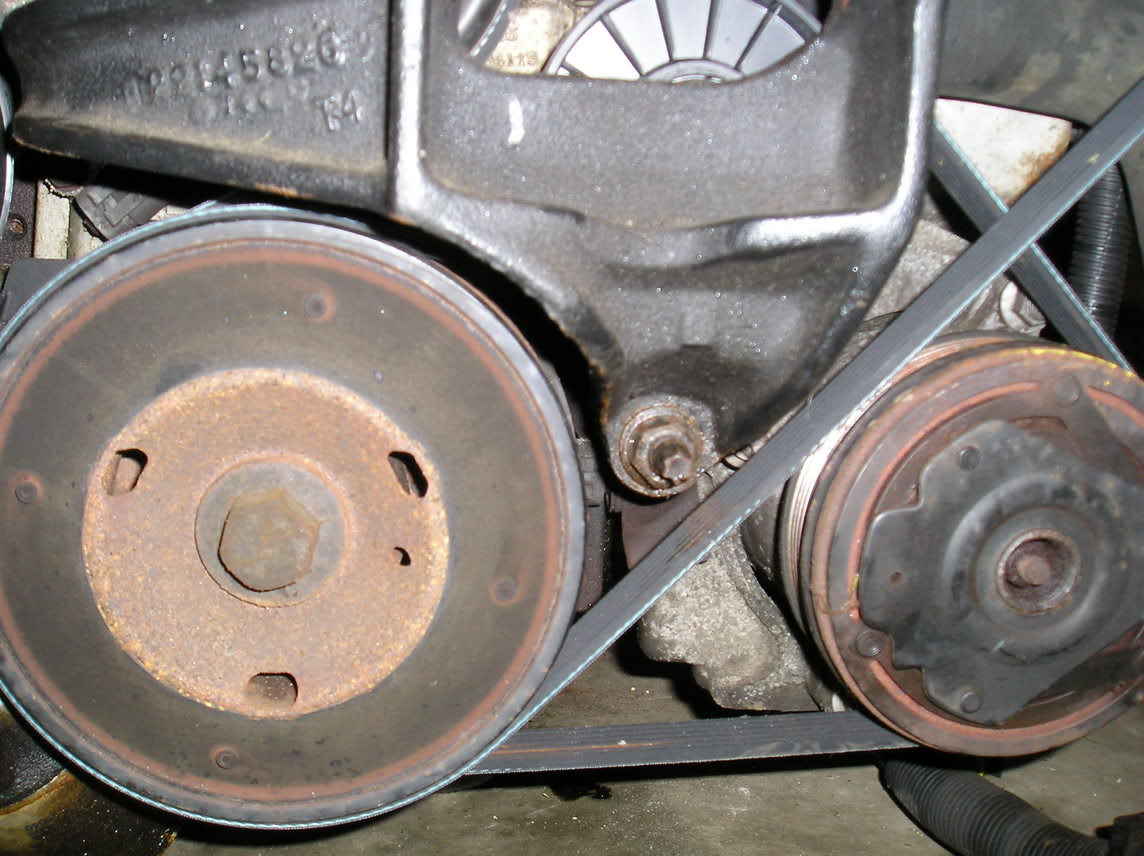

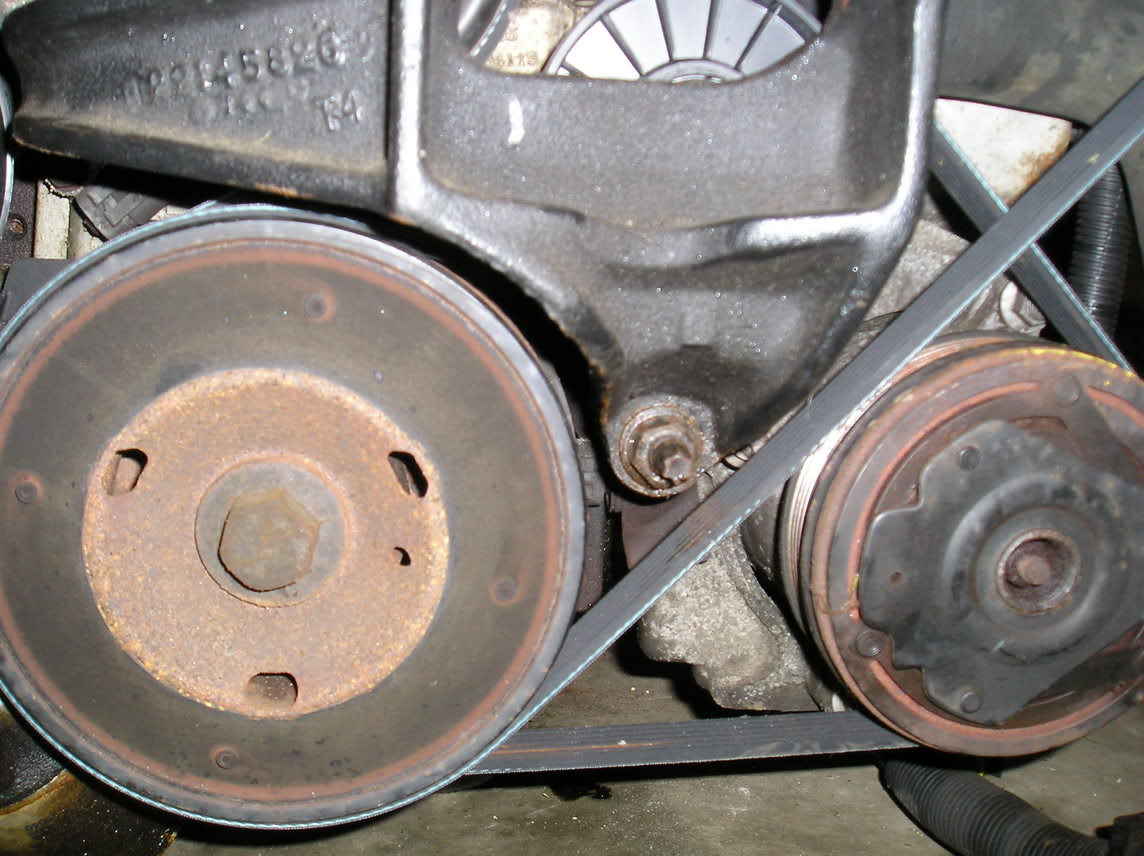

It happens that I have a 97 L67 sitting in my garage. On the floor and easy to take pics. The pulley on the left is the crank pulley the one on the right is the A/C. The stud you need is dead center.

Here'* a shot looking down inside so you can see the sleeve that will slide out.

Here'* a shot looking down inside so you can see the sleeve that will slide out.

#4

To answer your question, you need to raise your car to remove the wheel so you can then remove the splash shield to gain access to that bolt.

Here is a picture of my 93 with the wheel removed. You can see where the splash shield would be and you can see the AC pulley in the opening.

This will give you the easiest access to it. I suggest raising the front of the car as a whole (jackstands on each side) as this will kee it relatively lever left-to-right

Here is a picture of my 93 with the wheel removed. You can see where the splash shield would be and you can see the AC pulley in the opening.

This will give you the easiest access to it. I suggest raising the front of the car as a whole (jackstands on each side) as this will kee it relatively lever left-to-right

#7

Ok..While doing some other work to mine, I decided to put a new belt on too. I managed to get the nut off ok, but the stud does not want to seem to turn... I’m afraid if I pull on the ratchet too hard, it will strip the end of the stud. Any ideas?

I cant believe GM would make this in such a dumb A$$ way!

Thanks

I cant believe GM would make this in such a dumb A$$ way!

Thanks

#8

Thread Starter

Senior Member

True Car Nut

Joined: Jun 2003

Posts: 2,493

Likes: 0

From: Climax Springs, Missouri

i know its the same way on some of GMs other FWD sedans as well....it is very dumb to make such a commonplace do it yourself project so difficult, well its not hard, its just a pain in the ***

#10

Ok...I found a socket to fit over the end of the stud. Instead of the stud coming loose, the end of the stud is now toast....

Any ideas on how to get this thing out? I tried locking 2 nuts together on the end of the shaft, but they both just spun off too... Either the other end of the stud is all corroded, or the last person to change the belt, put it in with an impact gun!!

HELP!

Any ideas on how to get this thing out? I tried locking 2 nuts together on the end of the shaft, but they both just spun off too... Either the other end of the stud is all corroded, or the last person to change the belt, put it in with an impact gun!!

HELP!